1. Introduction

2. Update Safety Stock And Lead Time

3. View Forecasting Result

4. Generate Purchase Order

5. Additional Information

1. Introduction

Having difficulties knowing which products need to restock? Inventory Forecasting is here to help you get rid of all your worries. It estimates the stock that can last based on your current stocks and the sales performances. Hence, you are able to restock your stock in time.

📌Important Note:

You must have inventory items linked with your marketplace product listing. If you have not linked the marketplace product with the inventory items, refer to How To Use Bulk Inventory Linking.

2. Update Safety Stock And Lead Time

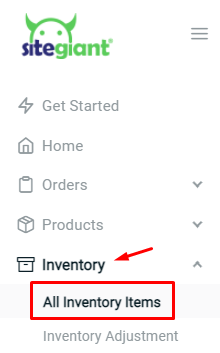

Step 1: Navigate to Inventory > All Inventory Items.

Step 2: Click the Item Name to edit the details.

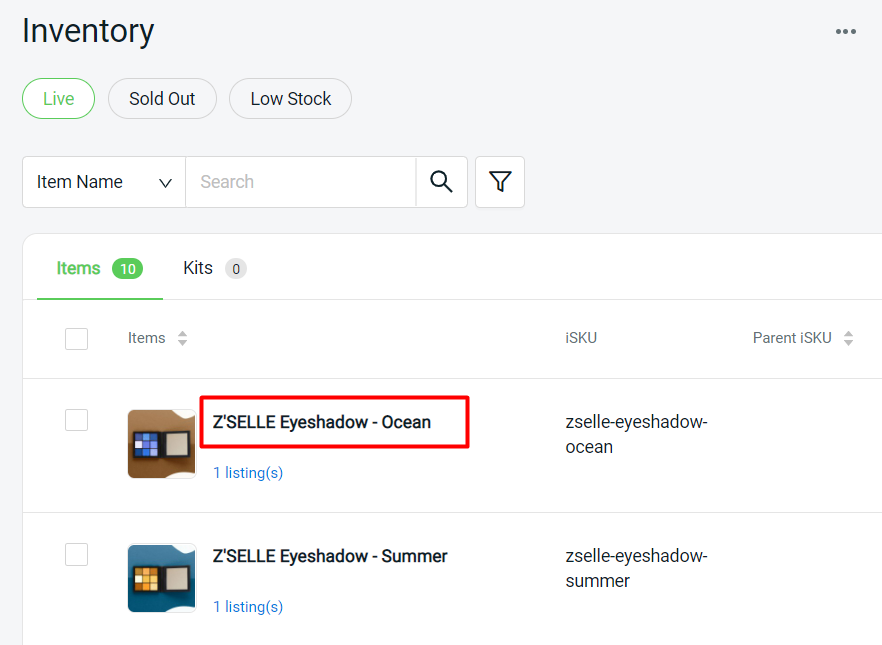

Step 3: On Item Info page, scroll down to Restock Details > fill in the Safety Stock and Lead Time.

Step 4: Save the changes.

💡Tips: You can also use Batch Edit tools to bulk update the Safety Stock and Lead Time for inventory items. May refer to How To Edit Inventory Item With Excel (Batch Edit).

3. View Forecasting Result

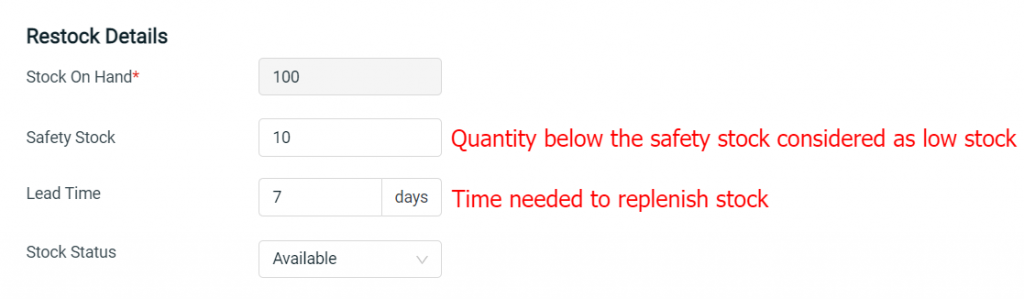

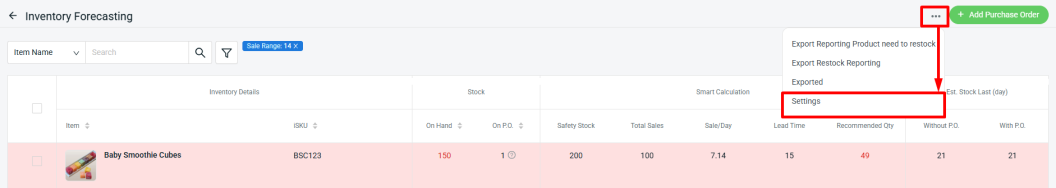

Step 1: Go to Inventory > Inventory Adjustment > Inventory Forecasting.

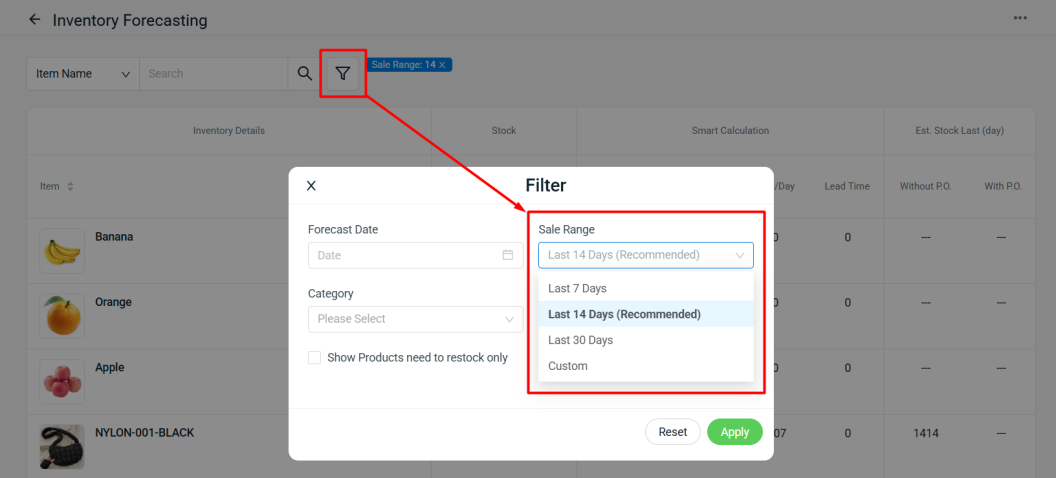

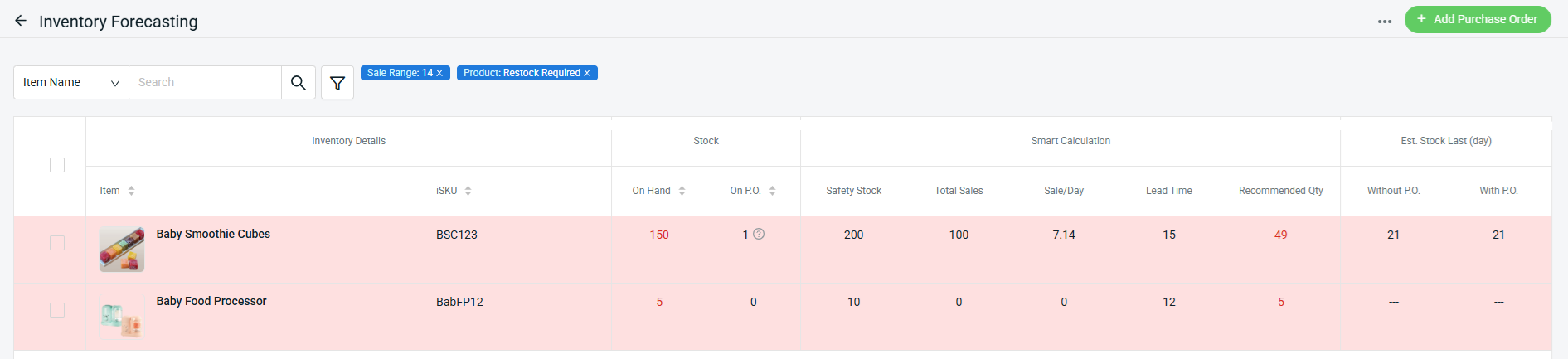

Step 2: Filter the Sale Range.

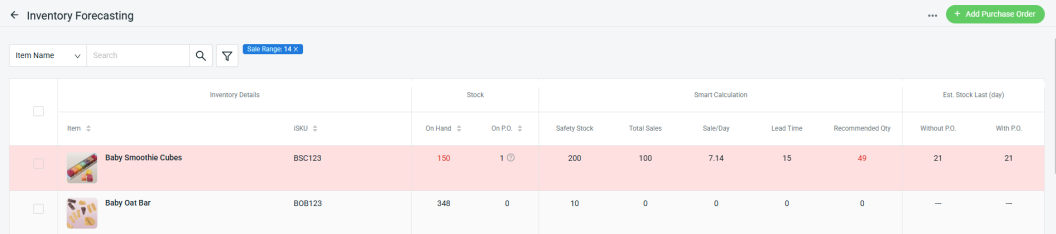

Step 3: The result after the filter will then be shown. The column inRed Highlightwill be the product that needed to be replenished.

Note: Click on the information icon ⓘ to view the Purchase Order (P.O.) details

Calculation:

Sale/Day = Quantity Purchased (Processed & Completed orders) ÷ Sale Range

Without P.O. = In Hand Stock ÷ Sale/Day

With P.O. = [In Hand Stock + Stock On P.O] ÷ Sale/Day4. Generate Purchase Order

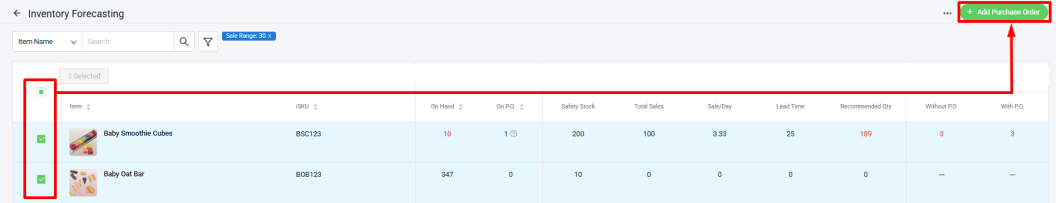

Step 1: Tick Item > click + Add Purchase Order.

📌Note: When creating a Purchase Order, the quantity will be prefilled using the Recommended Quantity.

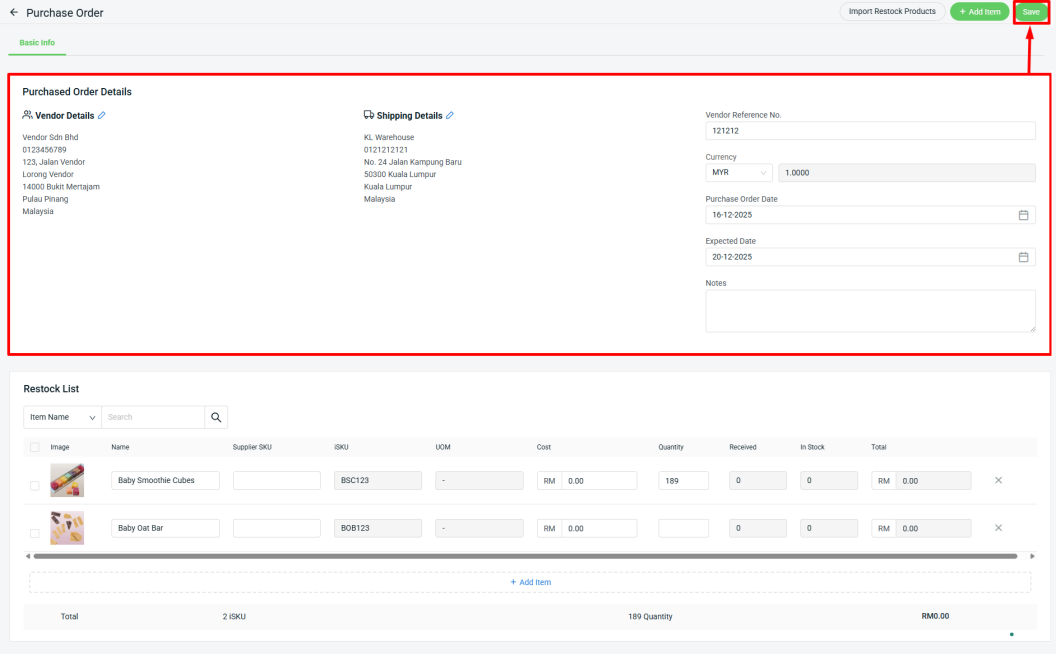

There are three ways to calculate the Recommended Quantity, and the system will use the highest value. The example calculation below will be based on the image above: 1. Based On Safety Stock Total Stock (On Hand)+ On P.O: 11 Safety Stock: 200 Recommended Quantity: 200 - 11 = 189 Stock 2. Based On Sales Per Day Total Stock (On Hand)+ On P.O: 11 Sales/day: 3.33 Lead Time: 25 Recommended Quantity: (3.33 x 25) - 11 = 72.25 ~ 72 Stock 3. Based On Sales Factor - Sales Factor will only apply when the inventory forecast is filtered based on Sales Factor.Total Stock (On Hand)+ On P.O: 11 Total Sales: 100 Sales Factor: 100% Recommended Quantity: (100 x 100%) - 11 = 89 Stock According to the the results above, the Recommended Quantity is taken from the Safety Stock calculation, as it provides the highest value of 189 stock.

Step 2: Fill in the Purchase Order Details > click Save.

💡Tips: Learn more about How To Create Purchase Order.

📌Note: If the Recommended Quantity is 0, the system will not prefill the quantity column. The merchant will need to fill it in manually.

📝Additional Information

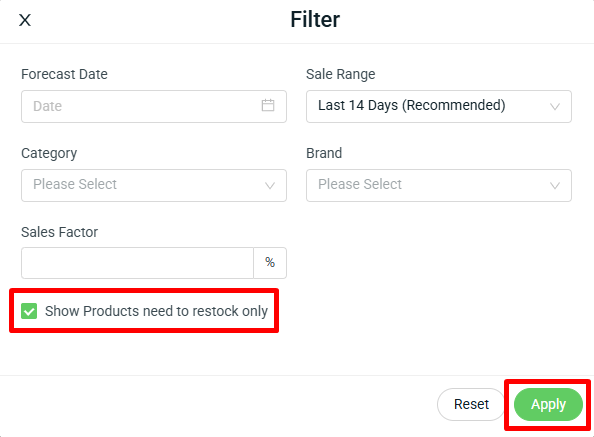

1. Show Products Need to Restock Only

You can filter to Show Products need to restock only. The product that is required to restock only will be listed.

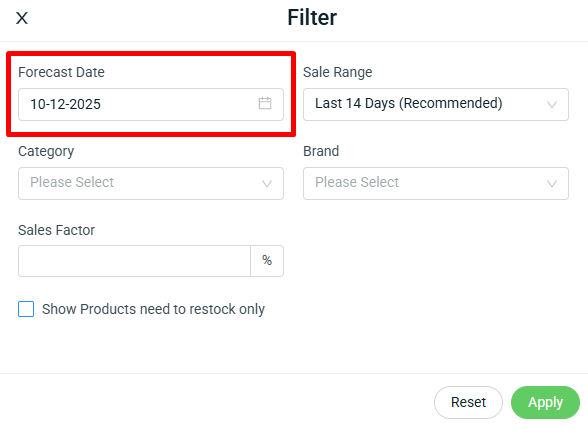

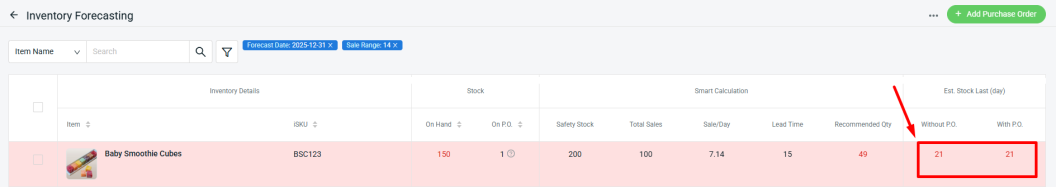

2. Forecast Date

Filter a Forecast Date to check whether the stock will still be able to last if the forecast date is reached

The column in Red Highlight and Wording is the product that needed to restock before the Forecast Date.

For example, if the product is estimated to last 21 days from today, and you set the forecast date to 21 days ahead. Then the result will be shown below:

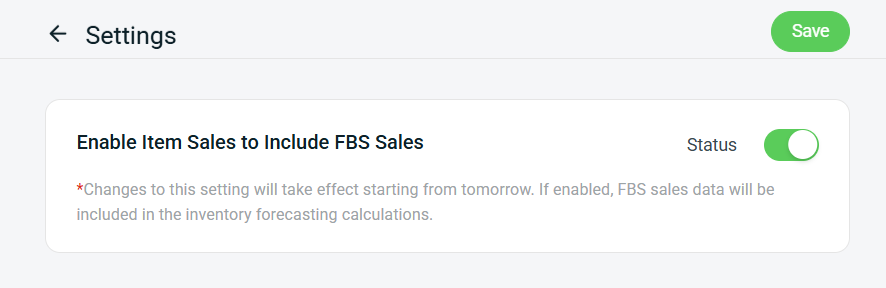

3. Enable Item Sales to Include Fulfilled by Shopee (FBS) Sales

Decide whether to include FBS sales data in the inventory forecasting calculations. By default, this setting is enabled. If you wish to exclude FBS sales, you may disable it, and the change will take effect the following day.

Total Stock (On Hand)+ On P.O: 11

Total Sales: 100

Sales Factor: 100%

Recommended Quantity: (100 x 100%) - 11 = 89 Stock

According to the the results above, the Recommended Quantity is taken from the Safety Stock calculation, as it provides the highest value of 189 stock.

Total Stock (On Hand)+ On P.O: 11

Total Sales: 100

Sales Factor: 100%

Recommended Quantity: (100 x 100%) - 11 = 89 Stock

According to the the results above, the Recommended Quantity is taken from the Safety Stock calculation, as it provides the highest value of 189 stock.